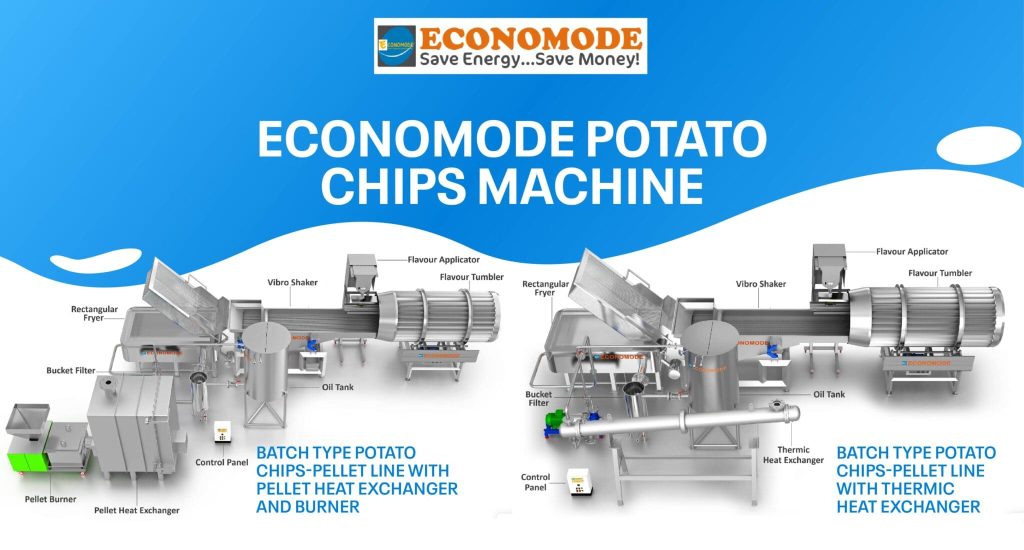

Economode Potato Chips Machine

Reading Time: 3 minutes

Economode automatic potato chips line. is an automated device that anyone can operate. It’s easy to clean and meets all hygiene requirements, making it an excellent choice.

The entire process of washing, peeling, slicing, de-watering, and frying fresh potatoes to produce tasty potato chips.

Economode Potato Chips Making Machine uses fresh potatoes as raw materials to produce delicious potato chips, It’s made of stainless steel so it’s easy to clean, saving time and money; moreover, the automated process is reliable in terms of hygiene too.

Potato chips go through a process in order to become chips. It must be able to withstand high temperatures in furnace oil in order to produce crispy chips. The chips may turn red in color if they cannot withstand the 195° C temperature of the oil

The potato’s skin needs to be removed because it is contaminated with dust, sand, and other particles and should be thrown away.

To perform the technique on a large scale, Potato peeling machine machine is required.

It has a plate with a silicon carbide covering that rotates on a motor-connected shaft. Because of the uneven surface of the plate, when it rotates, the potatoes in the upper section slide downhill, and the potatoes in the lower section rise. When the skin comes into contact with the silicon carbide plate, it erodes and is washed away by the constant flow of water.

A conveyer belt is used to move the potatoes between the processing stages. The conveyor belts are pushed by light vibrations to minimize damage.

The potatoes are placed into a vertical helical screw conveyer, which pushes the potatoes up to the automated peeling equipment through a conveyer belt while allowing stones to fall to the bottom. After being peeled, the potatoes are rinsed in cold water.

Using a rotating impaler presser, the potatoes are cut into paper-thin slices that range in thickness from 0.066 to 0.072 inches. While ridged potato chips are produced with rippled blades, regular chips are produced using straight blades. To remove the starch created when the potatoes are sliced, the slices are washed once more in cold water.

If the potatoes need chemical treatment to make them look better, it is done right away. The pH, hardness, and mineral concentration of the solution are all controlled while the potato slices are immersed in it. The slices pass through air jets that remove any surplus water as they run into 40-75 ft troughs filled with oil.

The oil is kept at a constant temperature of 350 to 375 degrees Fahrenheit. Paddles are used to gently advance the slices. As the slices fall from containers above the trough, salt is sprinkled on them at a ratio of around 1.75 pounds of salt for every 100 pounds of chips.

The packing machine receives the chips. The chips are weighed according to a known plan, and then a metal detector scans them once again for any foreign objects, such as metal fragments that might have come with the potatoes or been picked up during the frying process.

From a roll, the bags are dispensed. A central processing unit (CPU) programmed into the bag instructs the machine how many chips should be released into the bag. Gates open, letting the proper number of chips fall into the bag as it forms (Heat closes the top of the filled bag and the bottom of the next bag at the same time).

The necessary powdered spices are added to a drum and passed through with the flavored potato chips. The heated chips are forced out of the trough by a wire mesh belt. The filling manner has to be finished except for permitting too an awful lot of air into the bag and inflicting the chips to shatter. To fill the area in the bags, various producers appoint nitrogen. The sealed luggage is transported to a collator, the place they are manually packed into cartons.