- EconomodeFood

- January 26, 2023

- 3:16 pm

- One Comment

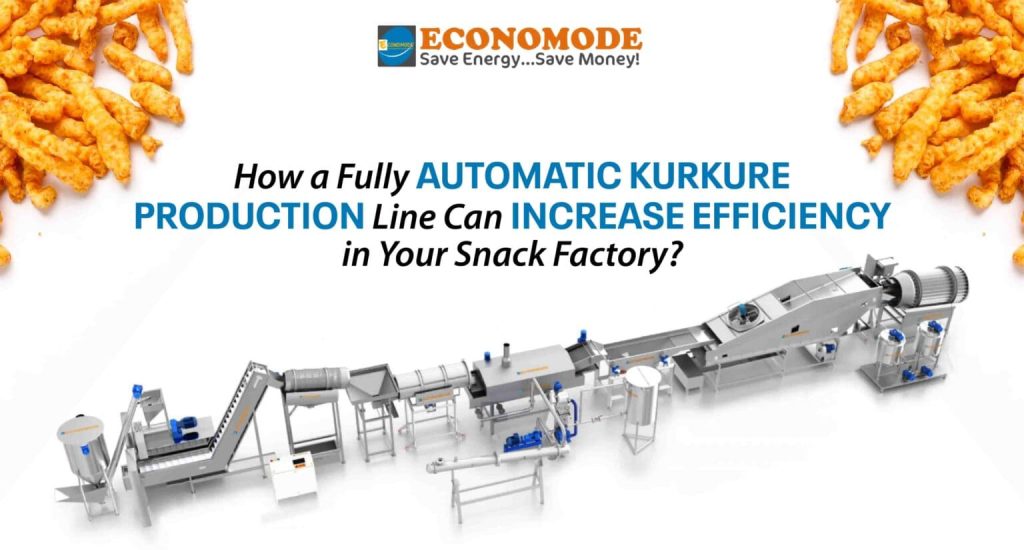

How a Fully Automatic Kurkure Production Line Can Increase Efficiency in Your Snack Factory?

Reading Time: 4 minutes

Kurkure is a popular snack that has been loved for its lip-smacking taste for decades. It’s a snack that comes in different flavors.

The fully fully automatic kurkure production line is the backbone of any snack factory and plays a vital role in increasing the overall efficiency of production.

If you’re a manufacturer of snack foods and other savory snacks, then it’s likely that to keep your business on track you need to bring your production on track. This means that you need to do everything possible to get back on track and increase efficiency with your production line

One way to do this is by investing in an automatic kurkure machine india which can help save time and money while also increasing output.

A kurkure line can increase efficiency in your snack factory by eliminating human error and allowing machines to do the wok instead.

It also ensures every step of the process runs smoothly without interruptions or mistake

Fully automatic kurkure production line– An Overview

A kurkure line is an assembly line that produces kurkure sticks. This process involves the use of machines to shape, cut and wrap the dough into pieces before they are ready for packaging. The machine used in this process is known as a fully automatic Kurkure production line (KPL).

It is very easy to operate, and it can be operated by one person or a team of a few people at a time.

It consists of various parts that are used for different purposes such as cutting, shaping and packaging before they are ready to be sold in stores all over the country!

An automatic kurkure machine india

is a system that can be used to produce Kurkure snacks at high volumes. This system consists of several components, including a hopper and conveyor belt, which move products from one station to the next. This fully automatic Kurkure production line

can make the kurkure sticks in a short period of time as compared to other types of equipment.

The kurkure machine is designed by manufacturers to meet all the requirements of a modern snack factory, such as segregation of raw materials and waste material; separation of various types or sizes; preparation of raw materials before they are used in the manufacturing process; mixing different ingredients together to create the most loved flavors!

A fully automatic kurkure production line would be an ideal option for snack manufacturers.

A fully automatic kurkure production line, as the name suggests, is a completely automated system that can produce kurkure at a much faster rate than traditional methods. It reduces the number of employees required to run the production line, which means you don’t need to hire more people or pay them high salaries if they are needed only once in a while. This also helps reduce costs associated with hiring and maintaining staff members who are not even directly involved in working on machine parts like assembly lines do today.

It lower cost because no labor needs training anymore before starting work on new machines and requires less space for storage because there is no need for inventory control

The fully automatic Kurkure production line is a great way to increase efficiency, productivity, quality and profitability. It reduces manual labour by as much as 70% while increasing productivity by 50%.

This would be an ideal option for snack manufacturers as it provides many benefits, including

Increased efficiency – this is obvious from the name itself, “automation”. The kurkure machine will increase your productivity and save you time and money by reducing labour costs, waste and water consumption. You can even expect to reduce energy consumption as well! since there is no human interference involved at all during the manufacturing process.

This system can handle large amounts of raw materials without breaking down due to mechanical failure or operator error – thus increasing output per hour worked by half compared with other methods!

Reduced labour costs – who doesn’t like saving on labour? With a fully automatic Kurkure production line

at your disposal, you won’t have to pay compensations to tons of workers. Not only does this mean no more overtime pay but also less employee turnover which means higher morale among employees as well! The fully automatic kurkure production line can reduce the amount of manpower required to make a particular product, which means you will save on payroll costs and other expenses related to hiring workers. This also means that there are fewer chances for errors or mistakes in the production process which in turn helps improve quality levels and ensure customers’ satisfaction levels as well

More consistency – it offers increased quality because each batch produced through automatic kurkure machine india has been tested beforehand so there will be no surprises when it gets dispatched out into stores.The kurkure line also increases product shelf life and improves quality and allows you to run multiple batches in one day! This means that there’s no need for your employees to do overtime coming up with excuses why they can’t complete their shift due to a lack of manpower or equipment issues.

Increased productivity – The automatic kurkure machine india

will work on its own, making sure that there are no losses in quality or quantity. It will operate non-stop until your snacks are ready for consumption! Reduced waste – as mentioned above, automation also means efficiency and reduced waste. The machine won’t make any mistakes when producing your snacks so you don’t have to worry about the waste of any raw material anymore!

All these benefits come with once a lifetime investment so what are you waiting for?

Conclusion

We hope that this article has given you a better understanding of what a fully automatic Kurkure production line

is, in addition to some ideas on how they could benefit your snack factory. We recommend starting with a small pilot project and then scaling up as necessary. The best part about installing an automatic kurkure machine

is that it can save money and increase efficiency without compromising quality or customer satisfaction!

This type of kurkure line is the best way to achieve your goals in a timely manner. This means that you can focus on other aspects of your business instead of having to worry about manual labor or dealing with a messy production process.