- EconomodeFood

- March 6, 2023

- 3:18 pm

- One Comment

NAMKEEN INDUSTRY: CHALLENGES VS SOLUTIONS

Reading Time: 3 minutes

In recent years the namkeen industry has reached its full potential in countries like India, Bangladesh, Kenya, Uganda, Nigeria, and UAE. Namkeen manufacturers have experienced a flood of changes over the past ten years as a result of changing consumer demands and tremendous innovation. These changes have been particularly significant for the industry.

Individual choices have become more diversified due to the immense options available in the market. Also, people have become much more considerate about their overall health and prefer items that are low in fat and sugar. Now, along with taste, quality is also given importance and those who are capable of providing these two simultaneously are leading the namkeen industry.

Economode food equipment manufacturing company offers namkeen-making solutions to namkeen makers by delivering top-notch namkeen production machines

and their accessories. Some of the key challenges and their solutions are mentioned below:

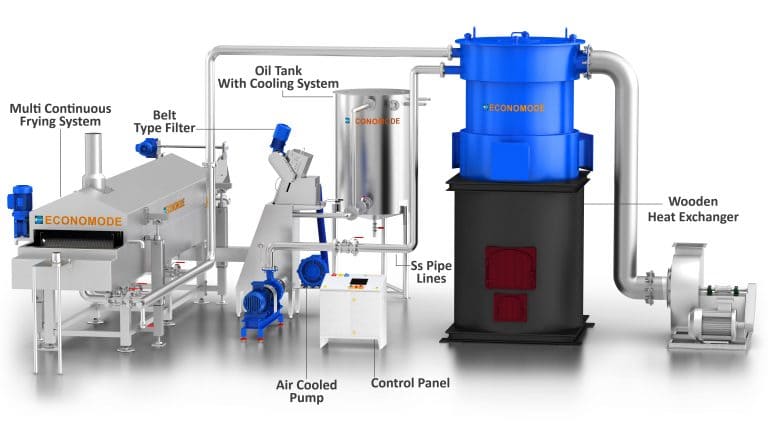

Multi Product Continuous Fryer With Wooden Heat Exchanger

Challenge 1: Inconsistent Quality

Inconsistent quality has become one of the most common challenges that a namkeen manufacturer

faces. During the namkeen production process, it becomes hard to maintain a consistent quality of the final product due to the inefficiency of

namkeen making machines

and labour.

Solution: Our namkeen-making production lines are designed to provide consistent quality of namkeen every time. We design machines that are equipped with advanced sensors that can detect any variations in the ingredients and make necessary adjustments to ensure the final product meets namkeen makers desired specifications.

Challenge 2: Slow Production

Slow production is something that has taken many namkeen businesses down. This generally happens due to the usage of old and rustic machines.

Solution: Once you install namkeen-making machines by Economode this challenge becomes totally negligible. Our machines are designed to handle high-volume production without compromising on quality. These machines are equipped with advanced automation and control systems that can speed up the production process while maintaining consistency.

Challenge 3: High Labor Costs

Indeed, “High labour costs” is the biggest challenge in the namkeen making industry. Industries that are using the old and manual method for namkeen production face this challenge

Solution: Our namkeen production lines are designed to reduce labour costs by automating most of the production process. These machines are easy to operate and require minimal supervision, freeing up your staff to focus on other tasks.

Challenge 4: Limited Product Range

What’s most challenging in namkeen making is that there is an infinite range of namkeen products that are offered in the market and demanded by end consumers. This has led small namkeen businesses to back off as they couldn’t provide so many varieties of namkeen

Solution: Here we again come to the rescue. Our namkeen machines are designed to produce a wide range of namkeen products. With our machines, you can easily switch between different recipes and customize your namkeen to meet your customer’s preferences.

Challenge 5: Maintenance Issues

Obviously, every machine requires proper maintenance and some cost has to be incurred there as well. Usage of too bulky and complicated namkeen machinery parts increases maintenance costs and difficulty.

Solution:

Economode namkeen-making machines are designed for easy maintenance and cleaning. Our namkeen production lines are built with high-quality materials and advanced technology to minimize breakdowns and extend the lifespan of the equipment. Additionally, our customer support team is always available to assist you with any maintenance issues that may arise.

Bottom line

To all of the above challenges, there is only a single solution, that is Installing Economode namkeen making machines today. We are here to help you eliminate all these challenges and save your namkeen business.