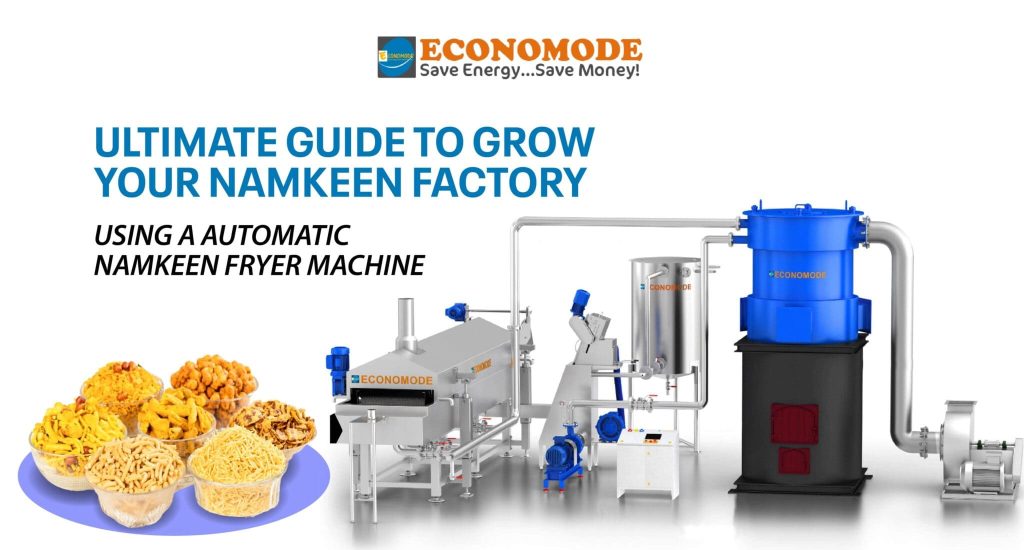

ULTIMATE GUIDE TO GROW YOUR NAMKEEN FACTORY USING A AUTOMATIC NAMKEEN FRYER MACHINE

Reading Time: 5 minutes

Introduction

Namkeen is a popular snack in India. It is made from different sorts of flours and various ranges of spices. The best Automatic namkeen fryer machine helps you make namkeens consistently at an affordable price. There are many ways to grow your namkeen factory, but one of the most efficient and cost-effective is by using this type of namkeen fryer. This machine helps you produce a wide range of namkeens at a faster rate and with less labour. You can get rid of the tedious and hectic challenges faced by using a normal machine.

It also helps you save money because you will not have to spend money on hiring labour to do this job. For example, if you have an independent store or restaurant, then it is possible that you may pay some workers every day to fry namkeens for your customers. If there are only two people working in your store, then it would be tough for them to handle all the orders at once. On top of that, they may need to work overtime so that they can meet their deadlines. That means that this will end up spending more money rather than generating more revenue.

Another advantage of using an automatic namkeen fryer is that it saves time because all you need is one person who knows how to use it well and can operate it properly without any issues whatsoever; this ensures that everything runs smoothly from the start.

How does a Automatic namkeen fryer machine work?

A Automatic namkeen fryer machine machine is a type of deep fryer that is designed for high-volume, continuous frying of snack foods such as Indian namkeen.

It typically consists of a conveyor belt that moves the namkeen through the fryer, allowing for continuous frying without the need for manual intervention. The conveyor belt carries the namkeen through a preheating area, where the oil temperature is gradually increased, and then into the fryer itself where the namkeen is fried at the desired temperature.

The namkeen is then moved through a cooling and draining area, where excess oil is removed before the namkeen is packaged or served. Some machines may have built-in oil filtration systems to prolong the life of the oil and reduce waste.

The automatic namkeen fryer also has temperature control, oil level control and an automatic basket lifting system for easy operation.

Namkeen making is the most profitable business in India

The namkeen industry is growing at an average rate of 10% per year, with an increase in demand for namkeens and a decrease in supply due to the increase in order for this product. It has become one of the most popular snacks among Indians as well as foreigners who visit our country every year.

Namkeen manufacturers face difficulties due to lower yields from their plants due to old technology and a lack of trained manpower; hence they need continuous innovation so that they can maintain their market share in this competitive market. The namkeen fryer machine has allowed factories to increase their production levels, resulting in increased sales and profits. It has also helped them to increase their profit margins by reducing the amount of time it takes to make namkeens. The namkeen fryer manufacturer also helps factories to install and start using fryer machines to reduce their operating costs and also guides them on how to produce more namkeens per day.

Why should you install a namkeen fryer machine today?

Namkeen making is an art and requires perfection

Namkeen making is a family tradition in India, where it has been passed down from generation to generation. Namkeen can be made from anything you like: potatoes, bananas, wheat flour or cornmeal (for example). But the most popular namkeen recipe is made with ground rice flour and water along with spices such as turmeric powder which gives your namkeen its yellow colour. You will find many variations of this traditional dish across India – one may have added sugar or butter instead of ghee (clarified butter). Everyone in India demands a flavorful namkeen and maintaining the flavour can be hard when following the manual process of namkeen making. The best way to get started with making delicious namkeen is by using this automatic namkeen fryer

Namkeen fryer machine brings consistency to fried snacks

This snack fryer machine brings consistency to your fried snacks. It is a very efficient device that can produce tasty, crispy and crunchy snacks in less time than other methods. This makes it ideal for making a fried snack that requires fast cooking. Moreover, it reduces the wastage of raw materials like oil and water required for deep frying and labour costs associated with manual labour involved during production stages when using traditional methods like batch cooking method.

Additionally, namkeen fryer manufacturer develops this machine to ensure consistent quality across all batches produced by using uniform temperatures throughout each batch cycle due to their built-in thermostat controls which ensure a constant temperature throughout the entire process cycle without any variation from one batch to another thus ensuring the same taste every time without compromising on quality standards at all levels.

Different types of Namkeen fryer machines

- Multi-product continuous fryer system: This type of fryer is designed for large-scale production and can fry a large quantity of Namkeen at a time.

- Batch fryer: This type of fryer is suitable for small-scale production and can fry a small batch of Namkeen at a time.

- Automatic fryer: This type of fryer comes with a built-in oil filter system and can automatically fry Namkeen without the need for manual intervention

Special Features of Namkeen Fryer Machine

Multi Products Fryer is Suitable for

-Floating products Sev, Ghathiya, Papdi, Ratlami, Bhavnagr

-Non-Floating products such as Pulses Chana Dal Peanuts, and Coated Nuts (Tasty)

Frying Control

Specially engineered multi-oil inlets maintain positive oil flow to clear the product infeed area & provide precise control of temperature & rapid adjustment to feed change.

Continuous Filtration

Circulating oil keeps fines in suspension for efficient removal. Every minute 100% of the system oil volume passes through a drum filter to remove 100% of product particles for the highest oil & product quality.

Oil Quality

Low oil volume and rapid oil turnover assure fresh products with a long shelf life.

Compact Design

Compact design results in cost-efficient operations by reducing space, energy & water usage.

Conclusion

In a nutshell, the namkeen fryer machine provides the best output lifetime once you invest in it. It’s also very simple to clean, maintain and operate. It helps you save time in the frying process, which means more money for your business!

With an automatic namkeen fryer machine, you can make namkeen in a consistent manner and give it to your customers only when they are ready. You will be able to make more profit from this because people won’t have to wait for days or weeks before their bulk order is delivered. This will also help you save time as well as money because no other snack preparation production line takes as less time as the namkeen fryer machine.

Check out for more: